Production Scheduling

Optimize your manufacturing process.

Optimize Your Resources

Maximize throughput and minimize downtime. Striven helps keep your production lines balanced, efficient, and responsive to changes in demand.

- Capacity Planning

- Material Requirements Planning (MRP)

- Production Order Management

- Machine & Labor Scheduling

Capacity Planning

Plan production capacity to meet demand without overextending or duplicating resources.

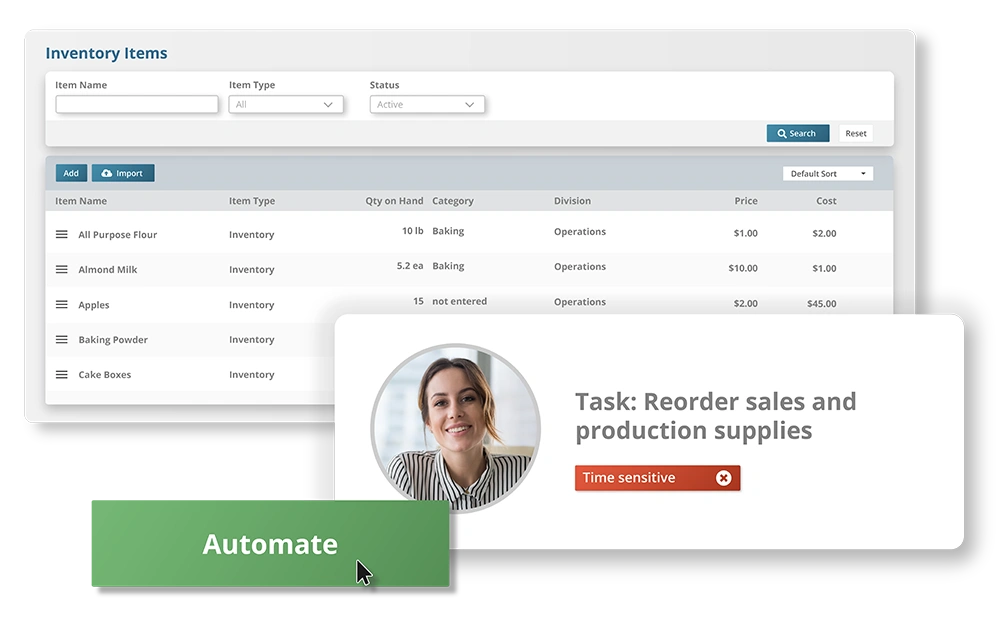

Material Requirements Planning (MRP)

Optimize availability and reduce waste with precise material requirements planning.

Production Order Management

Manage production orders from start to finish for smooth operations and timely deliveries.

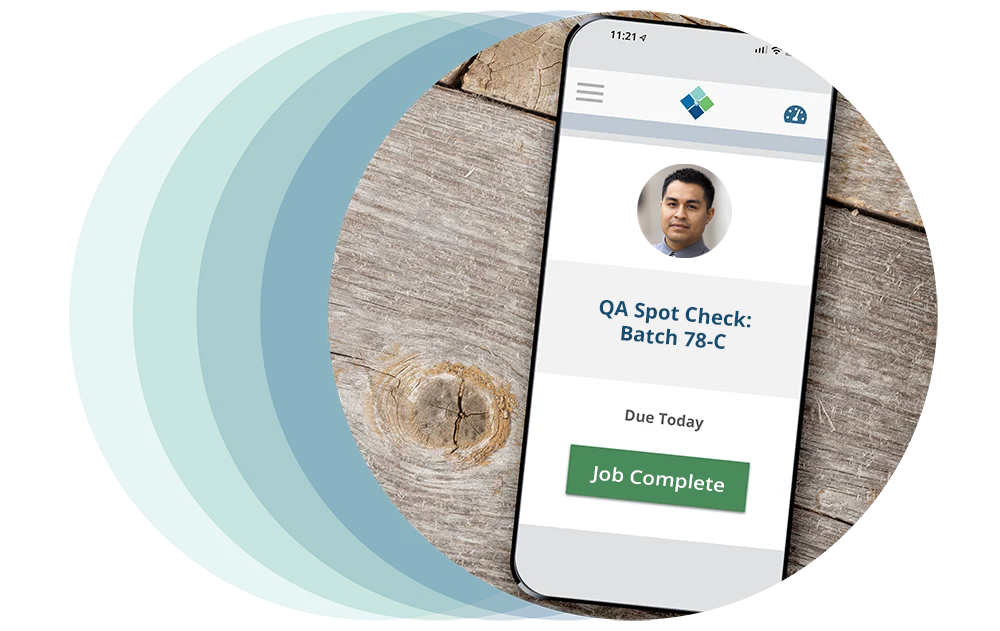

Machine and Labor Scheduling

Pair up machines and people efficiently to maximize productivity and minimize bottlenecks.

“Striven saves me so much time.”

“Not having to bounce between separate tools that don’t integrate well with each other is one of the most significant benefits for me. ”

—Ian Anderson, Associate Product Manager

Ready to try it? Start here.

Frequently Asked Questions

-

How does Striven help in dealing with production bottlenecks?

+

Striven identifies potential bottlenecks in production processes using real-time data and predictive analytics. It then suggests adjustments to schedules or resource assignment to prevent disruption and improve overall flow and efficiency.

-

Can Striven’s production scheduling adapt to custom manufacturing processes?

+

Striven is highly adaptable and can be customized to fit a variety of manufacturing processes, including job shops, batch production, and continuous flow operations. Its flexible scheduling tools allow you to tailor the system to meet your specific operational needs.

-

What kind of metrics can I track with Striven’s production scheduling system?

+

With Striven, you can monitor a broad range of metrics, including machine utilization rates, production cycle times, on-time delivery rates, and overall equipment effectiveness (OEE). These metrics provide valuable insights into the efficiency and productivity of your production operations

-

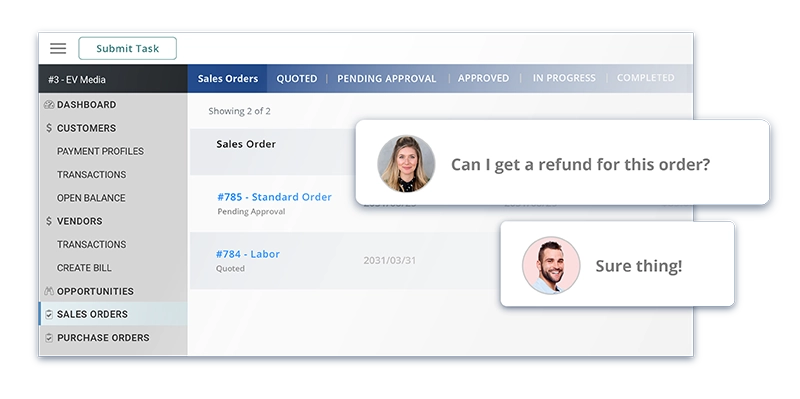

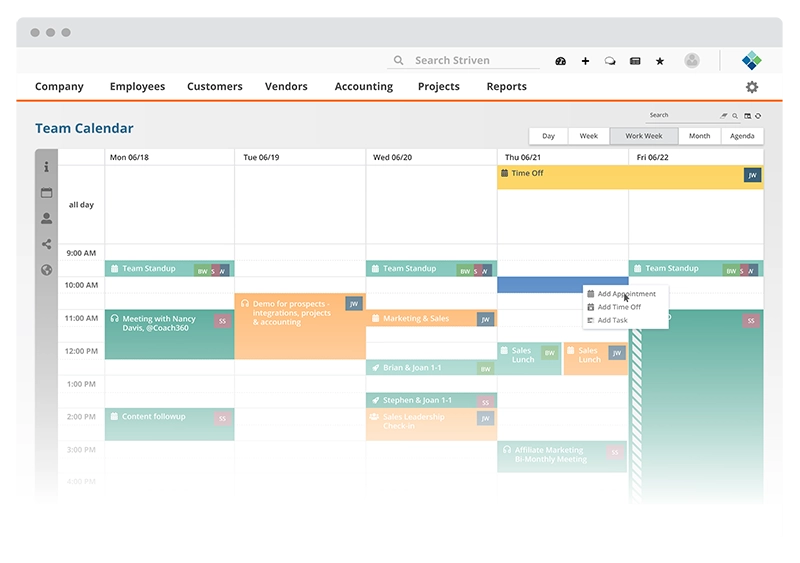

How does Striven facilitate communication and collaboration in production planning?

+

Striven enhances communication and collaboration by providing shared views of production schedules, real-time updates, and system notifications. All relevant team members are informed about schedule changes and production priorities.

-

Is Striven’s production scheduling system scalable for large manufacturing operations?

+

Striven’s system is designed to scale with your business, supporting both small manufacturers and large, multi-site operations. Its robust architecture ensures that the system performs efficiently, even as the volume of production data and the complexity of scheduling tasks increase.

-

How can Striven improve on-time delivery of products?

+

By optimizing production schedules and resource utilization, Striven can reduce lead times and production delays. Improvement in scheduling accuracy and efficiency directly contributes to better on-time delivery performance.

-

Can I integrate Striven with other ERP or MRP systems?

+

Yes, Striven is designed to integrate seamlessly with other ERP and MRP systems, ensuring that production scheduling is aligned with broader business processes and workflows. This integration helps maintain consistency and accuracy across all business operations.

-

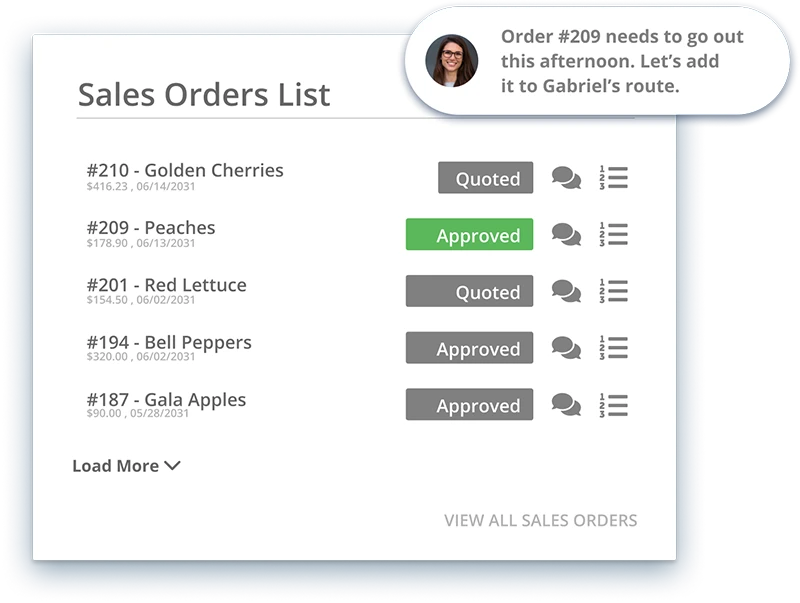

How does Striven handle changes in customer demand or urgent orders?

+

Striven’s production scheduling system is responsive to changes in customer demand, allowing for the rapid rescheduling of production tasks to accommodate urgent orders or shifts in market demand. Its dynamic scheduling capabilities ensure that your production is always aligned with current business needs, enhancing customer satisfaction and responsiveness.

Striven's Got You Covered

Whatever your business, Striven is here for you, making your workweek just a little easier.